|

|

||||||||||

Exafs determination of the composition and structure of transitional metal aluminides multilayer coatings

Related

publications:

1)

I.

Arčon, M. Mozetič, A. Zalar, A. Kodre, J. Jagielski, Nucl.

Instrum. Methods, B 199 (2003) 222-226

2) M. Mozetič,

A. Zalar, J. Jagielski, I. Arčon, P. Panjan Surface

and Interface Analysis, 34 (2002) 365-368

3)

I.

Arčon, M. Mozetič, A. Kodre, J. Jagielski, A. Traverse, J.

Synch. Radiation 8 (2001) 493-495

Introduction

Transitional metal aluminides are of great interest owing to their

industrial application. The Fe-Al solid solution, in particular,

shows good wear

resistance and excellent resistance to oxidation, sulphidation

and corrosion [1]. Fe-Al intermetallic

phases can be used as heat- and corrosion-resistant

coatings for bulk materials [2,3].

Thin coatings of pure FeAl phase can be prepared in different ways

including co-deposition of both materials, implantation of one

ion species into

the layer of the other metal, and consecutive deposition of Fe

and Al thin films [4,5]. The

multilayers are heated to appropriate temperature in order to obtain

a uniform coating. During the deposition at room

temperature

some migration of Fe into Al occurs. The FeAl phase is reported

to start growing at the temperature of about 200°C, but rapid nucleation

and growth

of FeAl is observed at the temperature of about 300°C. Between

400

and 600°C the FeAl phase is transformed into the Fe3Al lattice.

At 700°C

the ![]() -Fe

phase becomes dominant [5].

-Fe

phase becomes dominant [5].

In this paper we present a study of the phase formation in the

Fe/Al multilayers by ion beam mixing at different temperatures.

The composition

of the coatings is determined by AES depth profiling and the atomic

structure of the coating by Extended X-rays Absorption Fine Structure

(EXAFS).

|

|

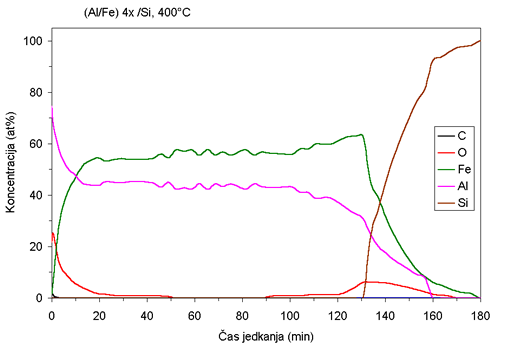

| Fig. 1. AES depth profiles of Fe/Al samples ion beam mixed at room temperature and at 400°C. |

Experiment

Four layers of Fe and Al were alternately sputter-deposited on

well-polished silicon substrates in order to obtain Fe/Al multilayer.

The respective

layer thickness was 20 and 30 nm, to ensure a 1:1 atomic composition

of as-deposited coating. The samples were ion beam mixed with the dose

3x10^15 ions/cm2 of Ar ions with the kinetic energy of 330 keV, at

different sample temperatures between room temperature and 400°C. The

composition

of samples was determined by AES depth profile analysis with the scanning

Auger microprobe (Physical Electronics Ind SAM 545 A).

Fe K-edge EXAFS spectra of the Fe/Al films and a reference Fe foil

were recorded at the X1 station in HASYLAB at DESY (Hamburg, Germany).

A Si(111)

double-crystal monochromator was used with 1 eV resolution at the Fe

k-edge (7112 eV) in combination with fluorescence detection technique

for thin film samples. The EXAFS spectra are obtained as the ratio

of the fluorescence detector signal and the signal of the incident

photon

beam from the ionization cell filled with nitrogen at abient pressure.

Typical measuring time for each fluorescence spectrum was 3 hours.

The EXAFS spectrum of 7 micron thick Fe foil was measured in a standard

transmission

mode.

|

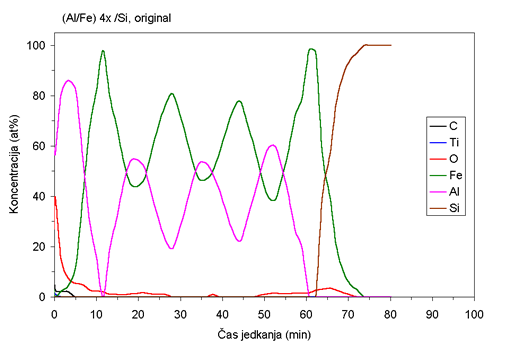

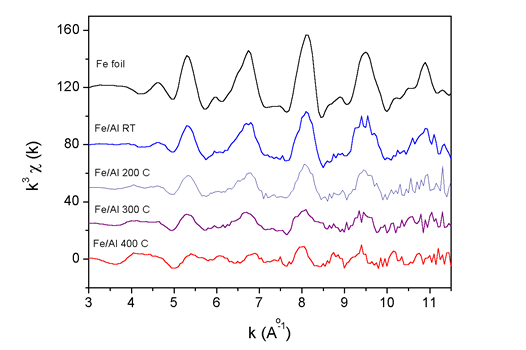

| Fig. 2. The k3 weighted Fe K-edge EXAFS spectra measured on the Fe/Al multilayer samples after ion mixing at room temperature (RT) and at 200°C, 300°C and 400°C. For comparison the spectrum of Fe metal foil is added. |

Results and Discussion

AES depth profiles of the as deposited sample and the sample mixed

at 400°C are shown in Fig. 1. Although the deposition was carried

out at

room temperature, the rather wide interfaces between the layers (Fig.

1a) indicated that some migration of atoms between the layers occurred

prior to ion beam mixing. Ion beam mixing at room temperature does

not produce substantial additional migration. However, extensive

migration of atoms between the layers is observed during ion beam

mixing at elevated

temperatures. At 300°C some of the layered structure still persists,

while at 400°C the coating becomes almost uniform (Fig 1b). It is

interesting that the composition of the Fe:Al in the sample mixed

at 400°C is not

1:1 as one would expect from atom ratio in as-deposited samples,

but rather 0.55:0.45. Some aluminum is evidently lost - probably

sputtered

off during the ion beam mixing.

EXAFS analysis is performed with the University of Washington programs

using FEFF6 code for ab initio calculation of scattering paths [6,7].

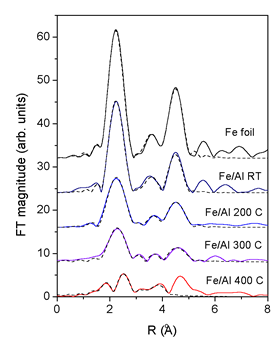

The basic facts about the structure can be deduced already from the

Fourier transforms of the Fe K-edge spectra (Fig. 2), even before the

detailed

quantitative analysis is performed. We can see that in the thin film

mixed at room temperature Fe exhibits pure bcc crystal structure, same

as in the reference metal foil. However, with increasing substrate

temperature, a gradual change from pure Fe bcc to a new Fe-Al alloy

structure is observed.

The mixing on the atomic scale is therefore more efficient at higher

substrate temperatures as already expected from the AES depth profiles.

|

| Fig. 3.The k3 weighted Fourier transforms of the Fe K-edge EXAFS spectra (k = 4.5 A-1 to 11.5 A-1) measured on the Fe/Al multilayer samples after ion mixing at room temperature (RT) and at 200°C, 300° C and 400°C. For comparison the spectrum of Fe metal foil is added. Solid line - experiment, dashed line – EXAFS model. |

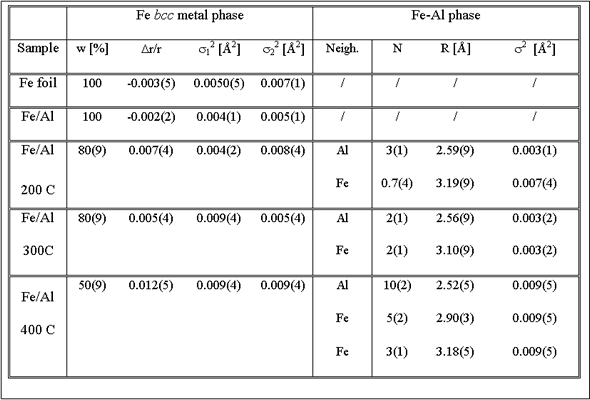

Quantitative EXAFS analysis is used to determine the ratio of the

two phases in each coating. FEFF model of the bcc crystal

structure of

Fe metal is constructed from the crystallographic data (the lattice

constant

a = 2.87 A [8]). The Fe atom is surrounded by 8 atoms at 2.49

A, 6 at 2.87 A, 12 at 4.06 A, 24 at 4.76 A, and 8 at 4.97 A in

the first

five

consecutive neighbor shells. The FEFF model comprises all single

scattering paths from this shells and all multiple scattering

paths up to 5.7

A. The model is calibrated by the Fe foil spectrum, yielding

an excellent fit for the region from 1.5 to 5.0 A (Fig. 2) with

just five variable

parameters: the lattice expansion ![]() , the amplitude reduction

factor (

, the amplitude reduction

factor (![]() = 0.81(5)), the zero-energy shift DEo, and the

Debye temperature

in modeling the Debye-Waller factors of all paths [6], except

the

first two, for which a separate factor (

= 0.81(5)), the zero-energy shift DEo, and the

Debye temperature

in modeling the Debye-Waller factors of all paths [6], except

the

first two, for which a separate factor (![]() )

is introduced. The shell coordination

numbers and unperturbed radii are fixed at their bcc values.

Best fit values of the parameters are included in Table 1.

)

is introduced. The shell coordination

numbers and unperturbed radii are fixed at their bcc values.

Best fit values of the parameters are included in Table 1.

The room temperature Fe/Al EXAFS spectrum is completely described

by the same Fe bcc model as in the Fe metal foil. Self-absorption

effects

of fluorescence measurements, which reduce the EXAFS amplitude

by a factor of 1.7, agree well with the estimate for the given

experimental

setup

by program code ATOMS [9].

EXAFS fit of the spectra of the FeAl coatings treated at higher

temperatures show that an additional aluminum-rich phase is present

beside the metallic

Fe (Table 1, Fig.2). In this phase Fe atoms are coordinated to

Al atoms in the first coordination shell at 2.5 A and Fe atoms

in the second

coordination shell at 3.1 A. Eventual further coordination shells

could not be distinguished

from the signal of the Fe metal phase. In Fe/Al coatings, treated

at 200°C and 300° C the Fe metal phase is still prevailing (80%),

while

at 400 C about half of Fe atoms in the coating are incorporated

in the Fe-Al

phase. In this case EXAFS fit was successful only up to 4 A from

the central Fe atom. The last peak in the spectrum at 4.7 A is

a combination

of single and multiple scattering contributions from both phases

and cannot be reliably modeled. Additionally, in the Fe bcc phase

of the

samples ion beam mixed at higher temperatures, the Debye - Waller

factors are increased, indicating stronger static disorder in

the metallic

Fe bcc phase.

From the structural parameters obtained by EXAFS fit it is not

possible to determine if the Fe-Al phase is fully crystallized

or if only sub-nano

scale crystallites are formed. Likewise, there is not enough information

to draw definite conclusions on the crystal structure of the observed

Fe-Al phase. The obtained local structure around Fe atoms is similar

but not equal to the one in the cubic FeAl crystal [11]. The presence

of cubic Fe3Al phase [11] can be completely excluded.

Table 1. Parameters of the nearest neighbors up to 3 A from the central Fe atom in the Fe foil and in the Fe/Al multilayer samples after ion mixing at room temperature (RT) and at 200°C, 300°C and 400°C.: w – fraction of Fe bcc crystal phase in the sample; (Dr/r) - Fe bcc lattice expansion, R – neighbor distances in Fe-Al phase, and si2 - Debye-Waller factor for individual shells. Uncertainty of the last digit is given in parentheses. |

|

Conclusions

A study of the phase formation in the Fe/Al multilayers by ion

beam mixing at different temperatures was performed. AES depth

profiles

of the samples

treated at room temperature and at 100, 200, 300 and 400C showed

gradual mixing of the layers with increasing temperature. At

400°C the mixing

was complete. Fe K-edge EXAFS data showed that at room temperature

there was no mixing on the atomic level. At higher temperatures a

new Fe-Al

phase appeared. Up to 300°C the fraction of this phase was only

about 20%, while at 400°C it increased to 50%. Although the AES depth

profile

of the sample mixed at 400°C showed a uniform coating, the mixing

on the atomic level was not complete.

Acknowledgment

Support by the Slovenian Ministry of Education, Science and Sport and

by Internationales Buero BMBF (Germany) is acknowledged. N. Haack

of HASYLAB (Germany) provided expert advice on the X1 beamline operation.

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

E-mail:iztok.arcon@p-ng.si Last change: 02-Jun-2006 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||